Manage Thermal Runaway Risk Around The Clock With a...

The inspection of electrical assets to monitor for abnormal operating conditions is fundamental to...

The inspection of electrical assets to monitor for abnormal operating conditions is fundamental to...

- 1 attendee

- Hosted by aldoradavids

- More

- Liked 0

-

The inspection of electrical assets to monitor for abnormal operating conditions is fundamental to ensuring safe and reliable operation.As such many countries have regulatory drivers and standards for industries to reference and establish best practices against. Improperly maintained electrical assets can expose your business to uncontrolled safety, downtime, equipment loss and regulatory driven compliance risks.

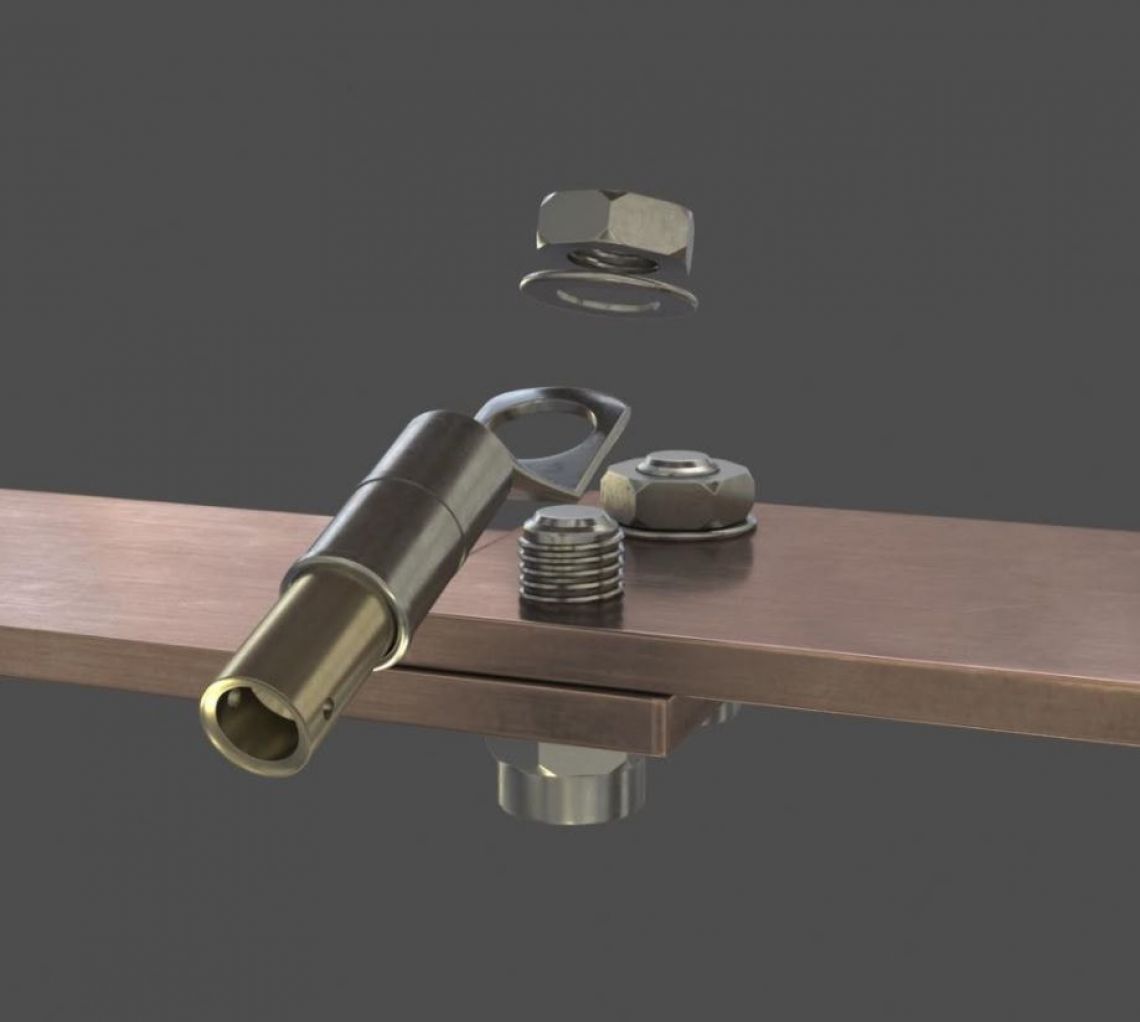

Loose connections are associated with over 30% of equipment failures (Hartford Steam Boiler Inspection and Insurance company). Is is not well understood that electrical connections have a design life as they appear very static in nature hower connection quality deteriorates with time due to impurity film buildup

“When current flows at the contact points, the respective electrons have to exit one busbar and enter the other. The microstructure of the busbar surfaces and the thicker or thinner impurity films are extremely important in this respect. The contact resistance Rü and therefore the joint resistance Rv increases with time as a result of impurity film buildup caused by chemical reactions, e.g. oxidation and corrosion. The busbar material can react with the ambient atmosphere or with the contamination and harmful gases it contains. Surfaces free of impurity films are achievable only in high vacuum.

Progressive film buildup increases the joint resistance Rv, heat losses and therefore the temperature of the joint, which in turn accelerates the chemical reaction producing the film buildup. This “vicious circle” of film buildup, heat loss and joint temperature can ultimately cause the busbar joint to fail totally as a result of overheating.” (Multi Contact, MultilamTechnology / 10.2004 / MC® - DTP).

Other causes of connection failure include thermal expansion & contractions, unbalanced and overloaded conditions, duty cycles, mechanical wear and stress, incorrect crimping of connections. improper cable training, vibrations and harmonics.

PyrOptic monitors electrical connections and contacts for degradation by sensing for over temperature conditions. A PyrOptic system consists of one or more PyrOnodes which are linked together by a continuous length of plastic optic fiber (POF). A PyrOnode will sever the POF at it’s location should the temperature rating be exceeded. A relay is used to automatically monitor the integrity of the loop and provide immediate feedback of the developing problem. In this way literally hundreds of points can be monitored on a single loop, the practical limitation typically being the level of segregation required for the application.

PyrOptic’s new concept is reliable, scalable, versatile and far more economical than the alternative technologies. PyrOptic is the first monitoring system suitable for mass deployment throughout electrical equipment and distribution systems enabling the elimination of routine inspections and thermography while offering superior risk mitigation outcomes.

PyrOptic offers the most reliable, economical and distrubutable fiber optic temperature alarm for electrical connections in the market. Our PyrOptic system consists of one or more PyrOnodes linked by a continuous length of plastic fiber optic (POF).For more details about please switchgear thermal monitoring and switchgear monitoring system visit our website.

Address:

Usa

Newyork

10001 -

Category

General -

Date & Time

Mar 21 2018 at 12:00 AM - Apr 22 2021 at 12:15 AM -

Location & full address

newyork -

Event Admins

aldoradavids